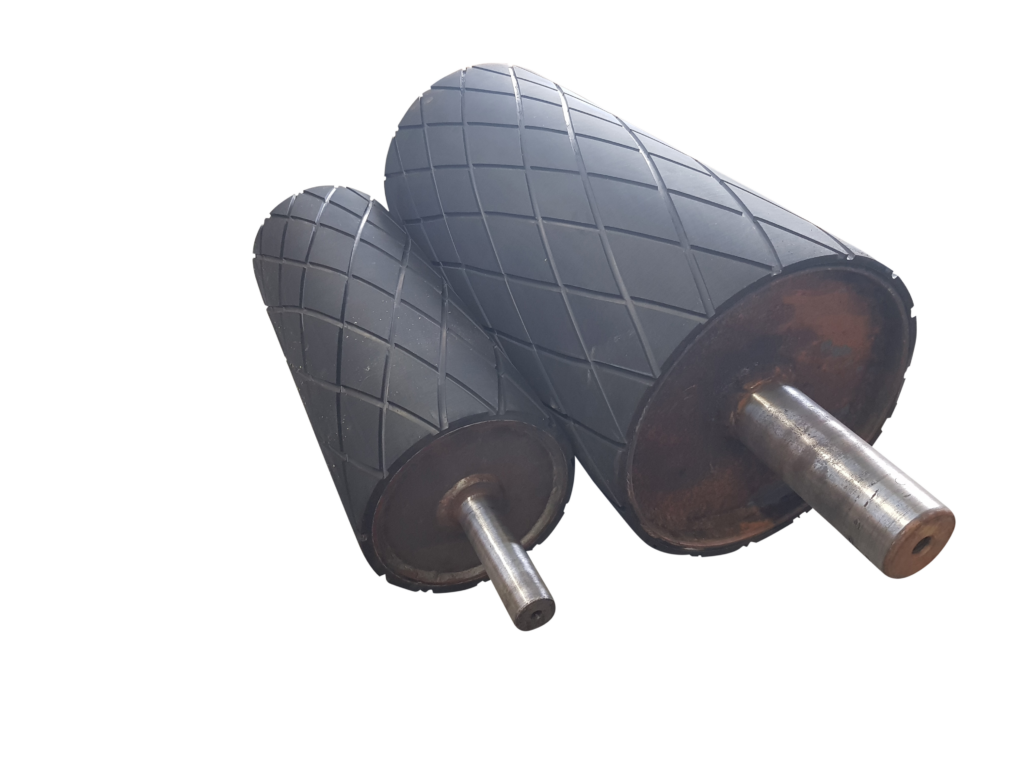

Transform your industrial equipment with AMES’s premium hot vulcanising rubber services. Our advanced vulcanisation process creates exceptional bond strength between rubber and metal substrates, ensuring lasting durability and performance in demanding environments.

Our Process begins with thorough shot blasting to prepare the surface, followed by the application of three specialised primers. Uncured rubber is then applied to create a permanent, high-strength bond. This process ensures superior adhesion and longevity compared to alternative bonding methods.

Do you have an application in mind that’s not listed here? Get in touch today and see how we can help you.

Do you have a project in mind but are unsure of what you need? give us a call and we’d be happy to answer any of your questions.